The TAPPI/ANSI T830 standard, developed jointly by the Pulp, Paper and Conversion Industry Technical Association (TAPPI) and the American National Standards Institute (ANSI), describes a test method to evaluate the frictional resistance of an ink film or fiber surface on container cardboard or corrugated cardboard. . In this method, ink friction testers are used and the following tests are performed mainly: dry rub, wet rub, wet bleeding or transfer, wet smear and functional scrubbing.

This test method evaluates the resistance of inks to dry or wet rubbing. It is also used to evaluate the dry or wet surface strength of coated cardboard, unprinted cardboard and other similar substrates, as well as smearing or bleed-through of inks. Sometimes this test method is used to distinguish between strong and weak ink films and their adhesion to container cardboard. This test method examines frictional resistance under different conditions than some other friction tests and should not be expected to produce the same results as other methods.

Preconditioning is required for samples prior to testing in accordance with TAPPI T402 Standard conditioning and test atmospheres standard for paper, board, pulp handsheets and related products. The test procedure is generally performed until failure is observed in the sample. Failure is defined by customer specifications and requirements and may include visible ink transfer to unprinted stock or copy paper, surface wear, or smearing of the printed image. The test procedure is carried out under various test conditions with different possible test speeds and contact pressures as desired by the customer. Samples are generally evaluated by visual comparison with internally maintained standards. The result is usually evaluated as pass or fail. It is also possible to evaluate samples using a density meter or spectrophotometer. The first reading before the friction test is set to zero and the change in density is reported after the friction test.

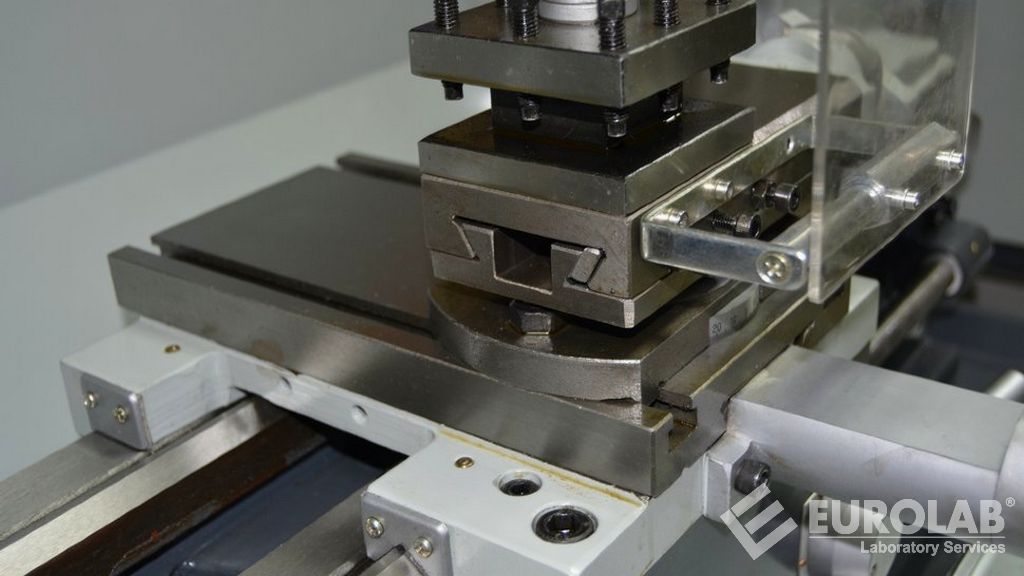

Among the numerous test, measurement, analysis and evaluation studies it provides for businesses in various sectors, our organization also provides ink rub test services of container cards within the scope of TAPPI/ANSI T830 standard, with its trained and expert staff and advanced technological equipment.